In an interview with Renate Eder , CCO at Vizoo GmbH,

Torben Böhm , Manager Technical Product Development

& Digital Innovation at bonprix shares how 3D is not only a tool

but an enabler to revamp outdated business processes

and prepare the fashion business for the future.

Company Profile

Industry: Retail Apparel and Fashion

Employees: 1400+

Location: Germany, France, Italy, & Poland

Vizoo Client Since: 2017

Industry: Retail Apparel and Fashion

Employees: 1400+

Location: Germany, France, Italy, & Poland

Vizoo Client Since: 2017

Key Takeaways

- bonprix reduced pattern development cycles from 9 months to just 6 weeks by implementing 3D technology & solutions.

- Consistent fit and fewer returns have been achieved across garment types.

- Supplier collaboration improved with the use of graded patterns and 3D visualizations, even supporting non-3D suppliers.

- 3D assets are now reused for marketing and e-commerce applications, reducing costs and increasing efficiency.

- Vizoo’s xTex™ Material Scanners and xTex™ Software played a central role in building bonprix’s reliable digital foundation.

Renate: bonprix is a role model when it comes to successful implementation of Digital Product Creation (DPC). What is so special about your approach?

Torben: When we started working with 3D technology in 2019, our goal was not just to experiment but make digital the new normal you can trust. Therefore, we were convinced that creating an accurate, solid, reliable foundation is the first step to take. Today, we see that this foundation we created, allows us to aim high with DPC.

Can you explain a bit more, what you mean by a solid foundation?

When starting with 3D, you need to be very clear on which pain point you want to solve. That is when we identified that we would like to improve our base pattern library regarding fit consistency. I believe many apparel brands can relate to this problem. In general, the garments are based on basic patterns. The better the base pattern, the better the final product.

We leveraged the speed and accuracy of the technology. With 3D, it suddenly became frictionless to iterate and review pattern changes. Thanks to our new basic pattern foundational library, we now create patterns in 6 weeks instead of 9 months. We speed up the process because no physical sample needs to be sewn up and there is no waiting time for shipping physical garments. We finalize the process by ordering one single physical sample to check the workmanship.

While our benefit is first and foremost speed and efficiency, the new fit consistency is an advantage for the client. All garment types have a consistent, reliable fit. I strongly believe that this would not have been possible without 3D, at least not in this form.

Amazing! This is a tremendous achievement. How does this affect your internal teams? In other words,

how does digital product creation fit in your business processes today and more importantly, did the implementation of 3D impact create a new way of working you aimed for?

At bonprix, we don’t have a purely design-focused role. Our creatives are product managers. These are the creative people utilizing our databases of fabrics and blocks. They generally have a clear idea of what they are looking for. They have the expertise and know the key parameters needed to receive valid suggestions from the databases.

With the help of DPC we significantly improved our tech pack handover to suppliers. In the old process the handover was just a 2D sketch and a measurement table. Today, our technical product developers provide the supplier with an already graded pattern. On top of the pattern, the 3D images we provide are a visual communication tool to the supplier. This is amazing because even suppliers who aren’t using 3D tools yet, benefit from the new process.

Consequently, this new way of working helped us to build important 3D competency in-house over the past few years, preparing our workforce for the future.

So how did you implement fabric digitization specifically and can you share some details about your process?

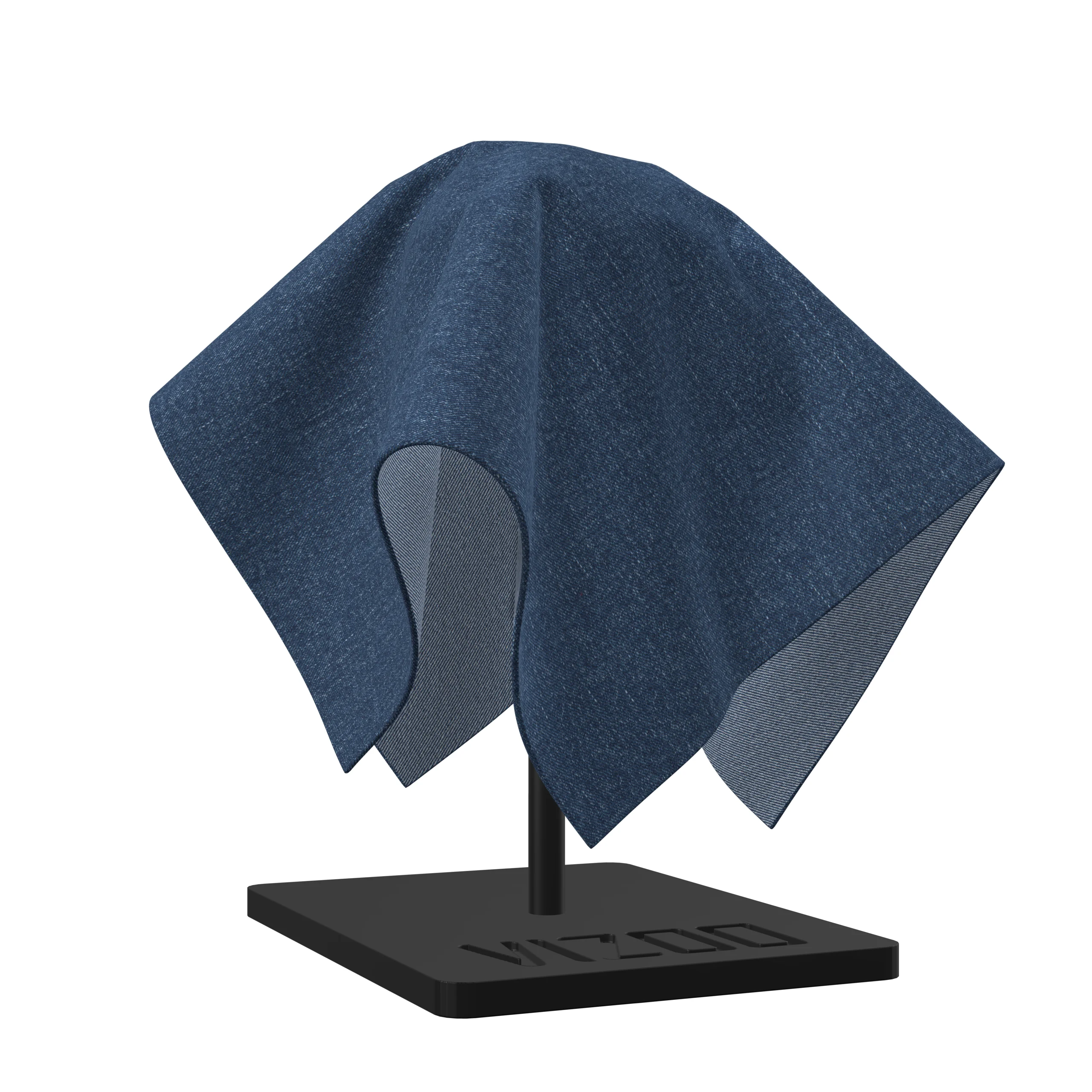

I do think it is obvious that our approach required high-quality digital fabrics. We started focusing on the visual appearance of the fabric and therefore chose the Vizoo xTex A4 scanner and xTex software and added physics from external tests. Today, we also capture the physical material parameters as we require a lot of fabrics for more accurate simulations using the virtual samples for fit checking.

The digitization is done by the bonprix fabric team to guarantee quick turnaround times and to build up the expertise quickly. This team first prioritized our standard fabrics and afterwards continuously digitized new additions. Today, we are digitizing all sorts of materials (like silk, knit, wovens, even sequins). And recently we also started scanning labels in preparation for CGI. To keep digital and physical workflows in-sync, the digital fabric data is stored in our material database alongside with the physical fabric information (with other fabric data).

How do you guarantee the quality of the assets

is consistent?

Materials are extremely important to us as we rely on the visual communication and fit. Therefore, we try to get as close as possible to a digital twin. The bonprix fabric team has all the expertise to create high-quality output according to our standards.

While Vizoo xTex is a central part, we add other peripherals like a lightbox. Especially for denim the color representation is very important. Additionally, we run a validation step so we can trust the digital fabrics. Therefore, we are checking the virtual drape in BrowZwear V-Stitcher software against the physical fabric swatch using the Vizoo drape reference. The approved fabrics are then saved as a grayscale version into our material management system.

I believe having high-quality assets also unlock other application areas. Are you leveraging your assets in other departments as well?

This is something we have just started. In my opinion the hardest part is done. We know the benefits of 3D assets and learned so much that we are ready to lift our process to the next level. It is time that we are not only using the assets internally, but the outer world starts benefitting from the digital files. This is why we are starting first tests to create marketing content as well as assets for our web shops. We are about to learn about this CGI process, like what is the right resolution and how perfect the images need to be. This is very exciting, because re-using existing assets is almost for free.

Once this is implemented, 3D will have a positive impact on reducing photo shooting cost. Additionally, having the marketing teams access the assets allows for almost instantaneous creation of content.

How do you see 3D and material digitization technology evolving in your workflow in the future?

First, the ideal scenario would be to receive digital fabrics from a fabric supplier. Second, we do expect that new technology like AI will facilitate the digitization workflow.

Bonprix speaks very openly about their 3D journey.

Is there anything you want to share with other professionals implementing their own DPC workflows?

Sure. First, 3D is not a tool which just magically works. 3D will reveal issues in your current process. Therefore, implementing 3D is less about technology and more about changing your processes. As an organisation, you must be prepared to face your issues and undergo a long-term transformation. Do not expect a short-term project and don’t give up just because it is getting hard at one point. Especially because 3D is very visual and there is little room for interpretation. We at bonprix we acknowledged our fit issues and decided to fix them with the help of 3D. It worked!

Today, bonprix has a leaner process from idea to production. In the past, the pattern was realized by the supplier – with lengthy iterations – today, the bonprix developers create and own the pattern. This new way of working has changed their job and responsibilities, and this would not have been possible without 3D.

”What's amazing is that the fit harmonization not only helped internal teams, but also improved our client's experience. Because the sizes of different products fit the same, there is no surprise any more how a garment would fit. And as a natural consequence, the fit related returns are less. This wouldn't have been possible without 3D technology and we at bonprix would never want to go back to the non-3D processes.

This case study interview is a joint collaboration between Vizoo and bonprix – September 2025.

About bonprix

Serving over 12 million customers, the e-commerce company is among the strongest revenue-generating brand concepts of the Otto Group. The diverse product range includes womenswear and accessories, complementary assortments for men and children, as well as selected home and living products. bonprix stands for fashion produced in-house and pursues an ambitious sustainability commitment.

About Vizoo

Vizoo is the leading supplier of solutions for the physically accurate digitization of material swatches in the fashion, sportswear and lingerie industry. Since 2013, the company has helped fashion brands and their supply chain to digitize their material processes and create digital twins of physical material samples. Their technologies are widely used from 3D Design to eCommerce in 45+ countries globally.

Ready to Digitize Your Business?

Request a live demo, share your 3D project needs, or ask questions about our capabilities.

Get in Touch