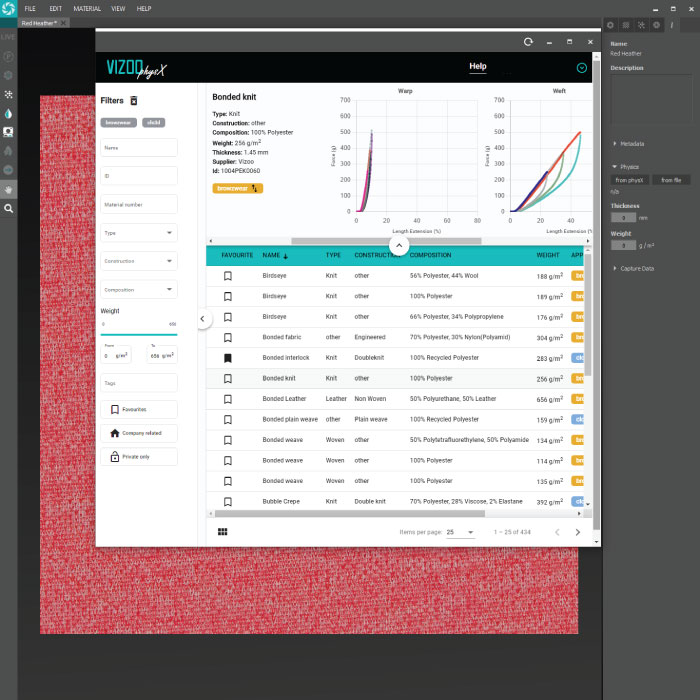

With physX™, you gain access to high-quality physical properties without running a measurement process.

10 times faster than traditional processes: While traditional fabric measurement processes require special hardware and take a significant amount of time (typically 45-60 minutes per 3D CAD application), physX™ makes high-end fabric for 3D apparel simulation accessible accessible within minutes – requiring less ressources for the overall digitization process.