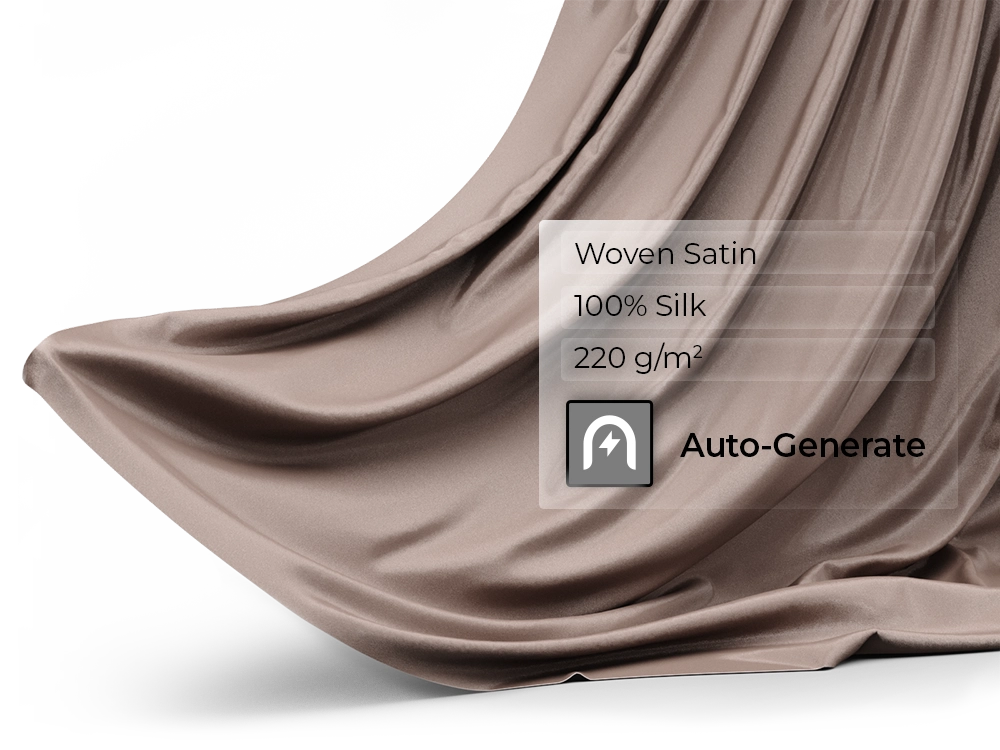

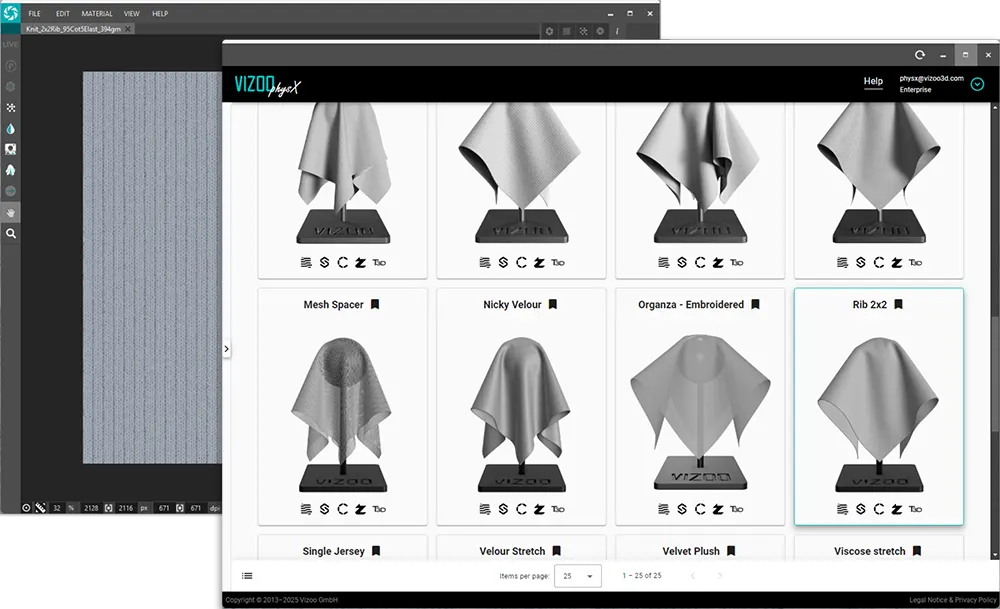

With physX™ products, you gain access to high-quality physical properties within minutes.

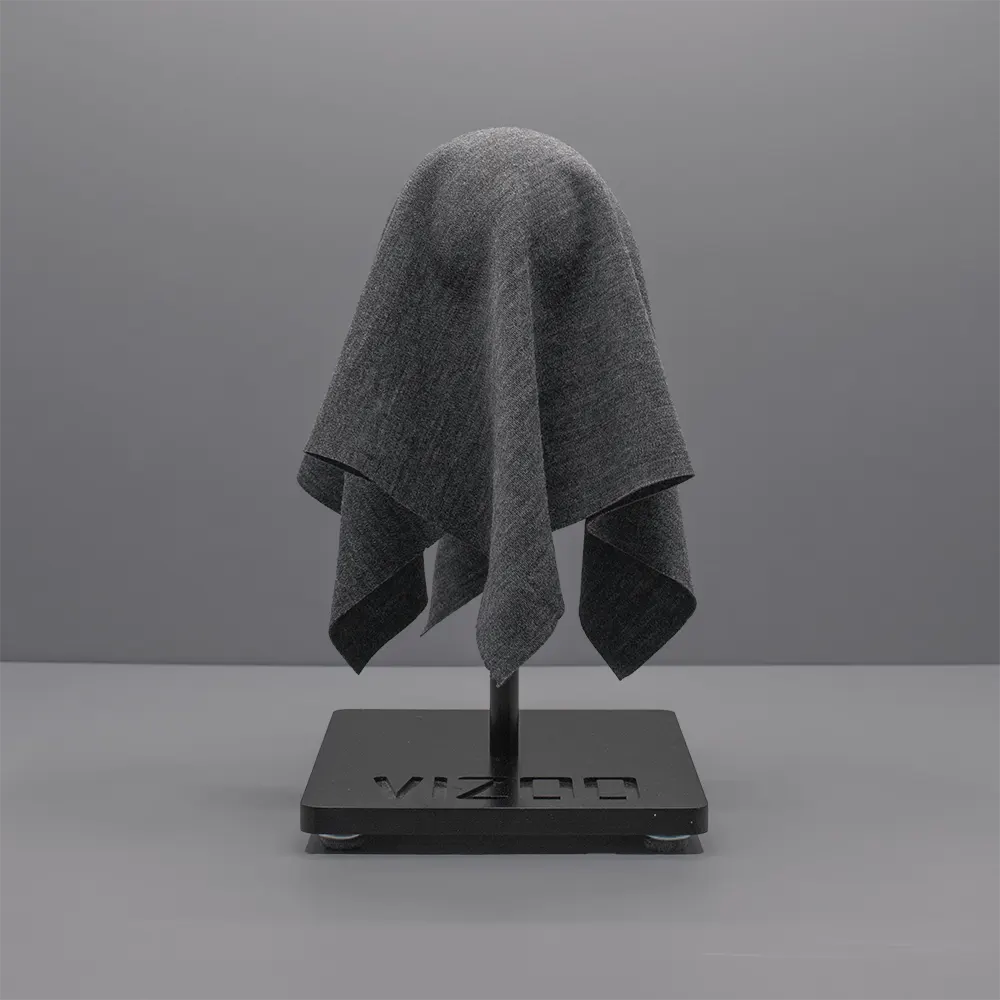

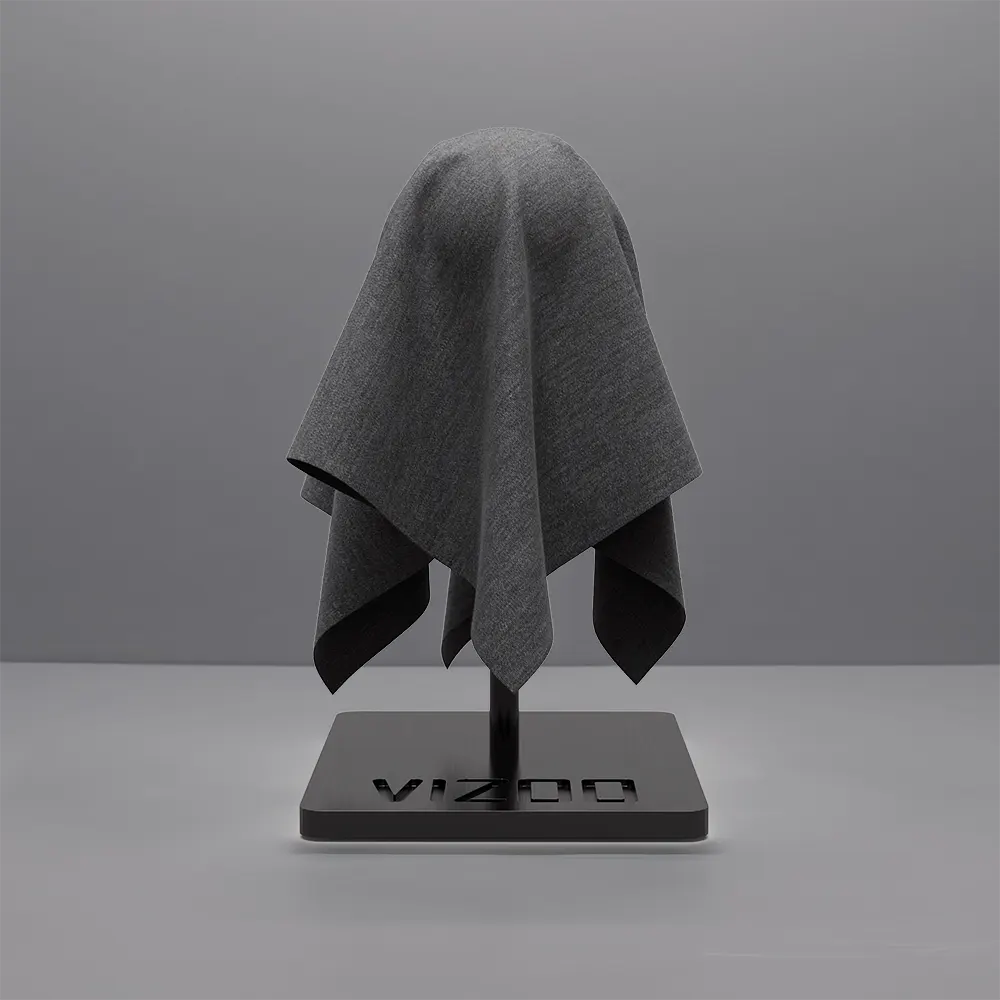

10 times faster than traditional processes: While traditional fabric measurement processes require special hardware and take a significant amount of time (typically 45-60 minutes per 3D CAD application), physX™ makes high-end fabric for 3D apparel simulation accessible and convenient – requiring less resources for the overall digitization process.